Focus on air compressor and vacuum system for 20 years

Hotline:

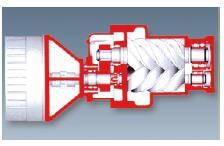

SM series explosion-proof mine underground screw air compressor

Product Classification:

Exhaust volume: 3.6 - 36 m3/min

The Edwards EDC series is a new generation of rugged single-stage dry claw vacuum pumps. The new series of EDC dry claw pumps adopt innovative design and set a new industry benchmark for the claw pump market.

Keywords: vacuum pump

Key words:

Product Details

The Edwards EDC series is a new generation of rugged single-stage dry claw vacuum pumps. The new series of EDC dry claw pumps adopt innovative design and set a new industry benchmark for the claw pump market. This series of pumps is simple, durable, and has a strong dust and corrosive gas handling capacity, is the right choice for your application. These new dry claw pumps are built to meet the standards and quality required by customers, providing you with a cost-effective and reliable solution to meet your needs.

Innovative structural materials and coatings allow the product to operate reliably over its service life, even under harsh process conditions.

Durable and durable

The simple design can quickly overhaul the pump cavity, which is convenient for cleaning the suction cavity when the suction cavity is contaminated by the entrained product.

Easy to maintain

Durable bearings and seals, gear box and pump chamber with patented isolated connections

Low maintenance costs

Ultimate vacuum, market-leading pumping speed and lower sustained vacuum

Improve productivity

like power consumption

Low cost of ownership

Low noise level

Silent operation

The partner of safe production can be directly used in various high-risk gas environment operations

Inlet capacity regulating valve

The large-caliber, low-pressure-drop design optimizes the suction efficiency. It can automatically adjust to the actual compressed air demand during operation, while only consuming the necessary power consumption, saving energy.

Couplings

The screw main unit and the main motor are connected by an elastic coupling, which has good centering, reliable connection, high transmission efficiency, and is convenient for oiling and maintenance of the motor. The single unit is light in weight and easy for on-site maintenance.

Thermal Control Valve

Set the opening and closing temperatures between 67-72°C to ensure that the return oil temperature is above the dew point to avoid damage to the rotor and bearings due to emulsification of the lubricating oil.

Oil filter

Adapt to harsh working conditions, more effectively filter out impurities and deterioration products in the lubricating oil, and ensure the service life of the main engine to the greatest extent.

High efficiency cooler

The air cooling system uses high-quality fans with low noise, and the increased heat dissipation area makes the heat dissipation effect more outstanding. The water cooling system uses a heavy shell and tube cooler with large capacity, water flowing in the tube, good cooling effect, suitable for high temperature environment. The straight-through pipe design is easy to clean.

Explosion-proof switch

Reliable design safely ensures stable performance.

It can be directly used in places with coal gas or gas outbursts in coal mines.

Reduce the number of pipelines required to deliver gas from the ground to the well; reduce the pressure drop caused by long pipelines; reduce the gas loss caused by condensation water produced by the temperature drop of compressed gas in long pipelines; reduce the gas loss caused by pipeline leakage.

The screw body with updated tooth shape has high efficiency, low noise, long life and low operation and maintenance cost.

Brand control components, stable and reliable.

The protective devices are complete and reliable.

Flexible movement and easy operation.

Air cooling parameters

| model | Exhaust volume (m3/min) | Exhaust pressure(Mpa) | Rated power(KW) |

|

SM37A

|

6.1 5.8 5.1 4.6 |

0.7 0.8 1.0 1.2 |

37 |

|

SM45A

|

7.2 6.8 5.9 5.1 |

0.7 0.8 1.0 1.2 |

45 |

|

SM55A

|

10.3 9.6 8.5 7.6 |

0.7 0.8 1.0 1.2 |

55 |

|

SM75A

|

13 12.3 10.9 9.8 |

0.7 0.8 1.0 1.2 |

75 |

|

SM90A

|

16 15.2 13.6 12.3 |

0.7 0.8 1.0 1.2 |

90 |

|

SM132A

|

21 20 19.7 17.7 |

0.7 0.8 1.0 1.2 |

132 |

|

SM160A

|

26.5 25.5 22.3 19.7 |

0.7 0.8 1.0 1.2 |

160 |

|

SM200A

|

32 30.4 27.4 24.8 |

0.7 0.8 1.0 1.2 |

200 |

|

SM220A

|

36 34.3 30.2 27.7 |

0.7 0.8 1.0 1.2 |

220 |

Water cooling parameters

| model | Exhaust volume (m3/min) | Exhaust pressure(Mpa) | Rated power(KW) |

|

SM90W

|

16 15.2 13.6 12.3 |

0.7 0.8 1.0 1.2 |

90 |

|

SM132W

|

21 20 19.7 17.7 |

0.7 0.8 1.0 1.2 |

132 |

|

SM160W

|

26.5 25.5 22.3 19.7 |

0.7 0.8 1.0 1.2 |

160 |

|

SM200W

|

32 30.4 27.4 24.8 |

0.7 0.8 1.0 1.2 |

200 |

|

SM220W

|

36 34.3 30.2 27.7 |

0.7 0.8 1.0 1.2 |

220 |

Product Consulting