Focus on air compressor and vacuum system for 20 years

Hotline:

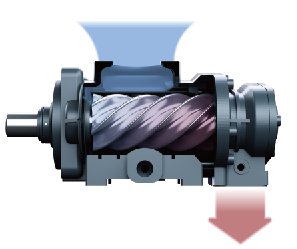

SL+ series low pressure screw air compressor

Product Classification:

Exhaust volume: 10 - 46m3/min

Power range: 30 - 185 kW 50 Hz

The Edwards EDC series is a new generation of rugged single-stage dry claw vacuum pumps. The new series of EDC dry claw pumps adopt innovative design and set a new industry benchmark for the claw pump market.

Keywords: vacuum pump

Key words:

Product Details

The Edwards EDC series is a new generation of rugged single-stage dry claw vacuum pumps. The new series of EDC dry claw pumps adopt innovative design and set a new industry benchmark for the claw pump market. This series of pumps is simple, durable, and has a strong dust and corrosive gas handling capacity, is the right choice for your application. These new dry claw pumps are built to meet the standards and quality required by customers, providing you with a cost-effective and reliable solution to meet your needs.

Innovative structural materials and coatings allow the product to operate reliably over its service life, even under harsh process conditions.

Durable and durable

The simple design can quickly overhaul the pump cavity, which is convenient for cleaning the suction cavity when the suction cavity is contaminated by the entrained product.

Easy to maintain

Durable bearings and seals, gear box and pump chamber with patented isolated connections

Low maintenance costs

Ultimate vacuum, market-leading pumping speed and lower sustained vacuum

Improve productivity

like power consumption

Low cost of ownership

Low noise level

Silent operation

Mainframe developed specifically for low voltage applications

• Directly output low-pressure compressed air at appropriate pressure, achieving greater exhaust volume with relatively small energy consumption

•The rotor clearance and main engine housing are precisely designed. Not only the exhaust source port is changed, but all designs of the main engine meet the requirements of large flow and low pressure, such as the enlarged bearing seat.

•The partial axial air intake design is introduced to fully utilize the effective length of the screw involved in compression, while reducing the operating noise of the main engine, effectively reducing radial unbalanced force, and extending the life of the main engine and bearings.

Independent oil pump design

• Ensure the operating oil pressure of the air compressor system. Intermittent operation, automatically sensing the oil pressure demand and starting, avoiding unnecessary energy waste.

•The oil pump also uses an IE3 motor.

Efficiently integrated overall design

Safe and efficient air filtration system

•Large dust particles in the air will fall into the rubber groove at the front end of the air filter housing along with the cyclonic airflow and will not be adsorbed on the surface of the filter element to cause blockage.

•Long-life filter element, large filtration area, and small air intake resistance ensure that the inhaled air is pure and free of impurities.

•The independent air filter inlet duct directly draws in cooler external air, making the air intake density higher and improving the efficiency of the whole machine.

Intake valve

• It integrates the functions of backflow prevention, oil cut-off, and capacity adjustment. The low pressure drop design makes the suction efficiency higher. It can automatically adjust with the changes in the actual compressed air demand during work, and the control of the empty vehicle pressure is more accurate, efficient and energy-saving.

Independent bearing lubrication

•The bearings are not lubricated by oil vapor from the secondary oil return pipe, and independent lubrication pipelines are used for bearing lubrication.

•Equipped with a separate oil filter to ensure the cleanliness of the lubricating oil.

Highly efficient and easy-to-maintain oil and gas separation system

•The enlarged oil fine separator design makes the oil-gas separation area larger. While achieving better filtering effect, it also reduces the pressure drop generated during the oil-gas separation process, making the entire air compression system more efficient.

•The oil and gas barrel cover uses Fu Sheng’s rotating shaft design, which makes it very easy to replace the oil fine separation element.

Unique cooling flow field

•The cooler is cooled by using a centrifugal fan to directly draw in cooler air from outside the unit, and the hot air is discharged directly from the top. The cooler itself also has a very large heat exchange area, which provides a better cooling effect.

•The centrifugal fan has a series of suction holes inside the unit that simultaneously discharge the hot air inside the unit to the top. This unique cooling flow field design keeps the temperature inside the air compressor at a low level and greatly reduces the noise generated by the fan action.

•The electric control box directly draws in cooler air from the outside, also ensuring better heat dissipation.

•When cleaning the cooler, there is no need to disassemble the air guide cover and door panel, just remove the cover.

•The air inlet of the whole machine and the air inlet of the cooler are equipped with high-efficiency filters to effectively prevent impurities from entering the machine body or adhering to the cooler, ensuring the cooling effect.

•The independent air filter air inlet channel directly draws in cooler external air, making the air intake density higher and improving the efficiency of the whole machine.

Series parameters

| model | Exhaust volume (m³/min) | Exhaust pressure (MPa) | Rated power (kW) |

|

SL+37A-3

|

10.65 | 0.3 | 37 |

|

SL+55A-3

|

16.5 | 0.3 | 55 |

|

SL+75A-3

|

22.0 | 0.3 | 75 |

|

SL+110A-3

|

31.0 | 0.3 | 110 |

|

SL+160A-3

|

46.0 | 0.3 | 160 |

|

SL+37A-4

|

10.0 | 0.4 | 37 |

|

SL+55A-4

|

13.5 | 0.4 | 55 |

|

SL+75A-4

|

18.1 | 0.4 | 75 |

|

SL+90A-4

|

20.0 | 0.4 | 90 |

|

SL+110A-4

|

26.0 | 0.4 | 110 |

|

SL+160A-4

|

36.0 | 0.4 | 160 |

|

SL+185A-4

|

46.0 | 0.4 | 185 |

Product Consulting